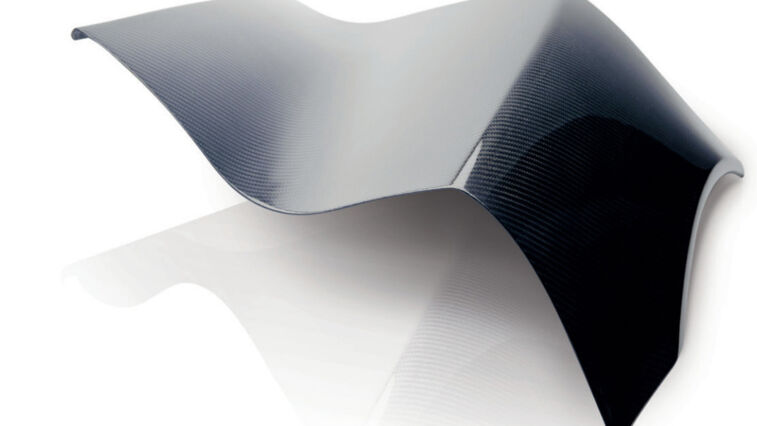

The shells of a rotor blade are made in sandwich construction. New materials such as ROHACELL® foam already enable the cost-efficient production of a wind turbine generator thanks to their excellent mechanical properties at low foam densities.

While onshore wind farms are less expensive to generate wind power, the advantages of offshore wind parcs are higher wind speeds at sea, which allows more power to be produced. ROHACELL® WIND-F is GL certified and meets all blade requirements.

Offshore wind turbines have to withstand the harshest climatic conditions and last around 20 years. ROHACELL® WIND-F ensures excellent fatigue properties of the blades ranging from ≥ 18.

Rotor blades are among the most important components of a wind turbine and represent the highest assembly cost of the entire wind turbine. ROHACELL® WIND-F helps to save energy costs due to its lightweight.

Lower energy cost through extended blade lifetime

ROHACELL® FOAM FOR SUSTAINABLE WIND ENERGY

With ROHACELL® Wind-F, we have developed an innovative solution for the special requirements of the wind energy industry. The combination of very low weight, high quality and the capability to support highly efficient production processes enables you to develop a cost-efficient wind turbine generator system.

How do our high performance foams for the wind energy market help combat climate change?

The share of wind power in the sustainable energy mix is constantly increasing just because wind power does not pollute air or water, does not require cooling water, reduces dependence on electricity from fossil fuels, which significantly contributes to the reduction of carbon dioxide emissions.

Nowadays, manufacturers of wind turbine blades have to face the challenges of more cost-efficient, less energy-consuming production methods and reduced blade loads.

High performance sandwich cores for efficient manufacturing of wind turbine blades

ROHACELL® WIND-F is the product of choice when it comes to lower cost of energy in wind turbine generator (WTG) design. The innovative kind of foam provides not only outstanding mechanical properties at foam densities as low as 50 kg/m3 by meeting the GL requirements at these low densities.

But the product also scales down resin adsorption and thus cost in comparison to other core materials. (45% less than PVC). Furthermore ROHACELL® WIND-F is characterized by low specific mass with focus on the highest possible manufacturing quality which contributes to optimal strength, stiffness, and durability of onshore and offshore wind turbine blades.

Key Benefits of ROHACELL® for wind turbine blades

- Lower turbine loads through less blade mass

- Lower foam core density

- Core shaping versatility

- Reduced cycle times (pre-curing and post-curing)

- Extended service life of the blades

- Significantly less resin adsorption and thus cost reduction compared to other cores

- High temperature curing through processing up to 150 °C

- GL certified